Cryogenic Ultra-Freeze Tunnels are Built to Preserve Quality

Designed to excel in demanding environments, our Ultra-Freeze Tunnel Freezers deliver exceptional product quality. Made in the USA, these freezers are engineered to maintain product integrity while minimizing dehydration, making them the perfect solution for a variety of industries.

Efficient Freezing

Products pass through insulated modular tunnels equipped with controlled temperature zones and adjustable belt speeds to ensure fast and efficient freezing while controlling operational costs.

Built for Durability

With a fiberglass outer shell, the Ultra-Freeze boasts exceptional strength, durability, and a reliable design that holds up in tough environments. Stainless steel components provide long-lasting performance you can depend on, and our innovative doors are designed to resist freezing shut.

Easy Cleaning

Our unique cylindrical design eliminates hard-to-reach corners, streamlining cleaning and promoting maximum airflow for consistent and dependable freezing. Built with food-grade materials and hygienic, easy-to-clean surfaces, the Ultra-Freeze meets the highest sanitation standards, making it a perfect choice for individual quick freeze (IQF) food processing environments.

Advanced Temperature Control

The system's precise temperature control prevents dry ice buildup by optimizing CO2 injection rates based on product heat loads, reducing resource use and saving energy.

Reliable Gas Movement

We offer 1” insulated copper pipes that are ideal for cryogenic setups, to deliver fresh CO2 or LN2 to freezers safely and efficiently. Our high-pressure direct-drive exhaust blowers are equipped with a housing and blower wheel designed to move used LN2 or LCO2 through long airways.

Drive Down Freezing Processing Costs While Saving Space and Time

The initial investment in an Ultra-Freeze Tunnel is lower than a mechanical freezing system, and the turnaround time for delivery, installation, and operation is faster. With 3-Tier options, you can save valuable space while benefiting from greater processing flexibility.

Modularity Speeds ROI While Scaling for Future Demand

The Ultra-Freeze System’s modular design can grow with your business, allowing for easy and cost-efficient expansion as your needs evolve. We offer 1 or 3-tier modules to meet your volume and space requirements.

Freeze Tunnel Options To Meet Your Unique Needs

Depending on your specific application and environment, consider the following Ultra-Freeze options

Directional product transfer devices to maintain orientation for automated packaging.

Smooth tray transfer devices to eliminate product flipping in three-tier freezers.

Side product guards to ensure proper product positioning on the belt.

Nitrogen (N2) or Carbon Dioxide (CO2) dual cryogen capabilities.

Custom straight-line conveyer configurations based on your specifications.

| Specifications | ||

| Conveyor Width | 30" width | 48" width |

| Freezer Width | ||

| Door Closed | 4'10" | 6'2" |

| Door Open | 6' | 7'6"" |

| Product Loading Height (+-1.5") | ||

| 1 Tier | 35" | 35" |

| 3 Tier | 40.5" | 40.5" |

| Product Discharge Height (+-1.5") | ||

| 1 Tier | 23.5" | 23.5" |

| 3 Tier | 28.5" | 28.5" |

| Product Clearances | ||

| 1 Tier | 8.75" | 8.75" |

| 3 Tier | 4" | 4" |

| Electrical | 230V 60hz standard | |

Ultra-Freeze Specifications

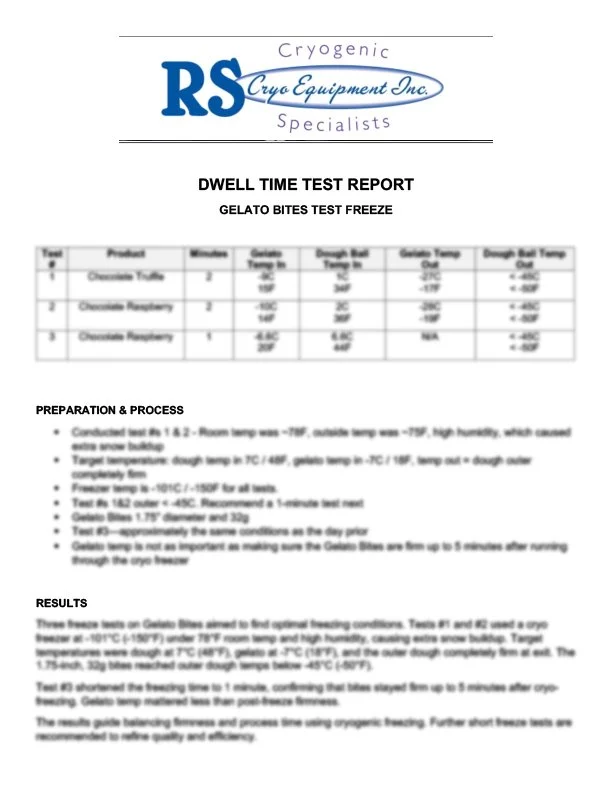

RECEIVE A FREE DWELLTIME TEST REPORT FOR YOUR PRODUCTS

Ultra-Freeze Tunnel Engineering Documents

Contact us for more details.