Made in America

Where Can We Help You

Welcome To RS Cryo Equipment:

The Cryogenics Specialists

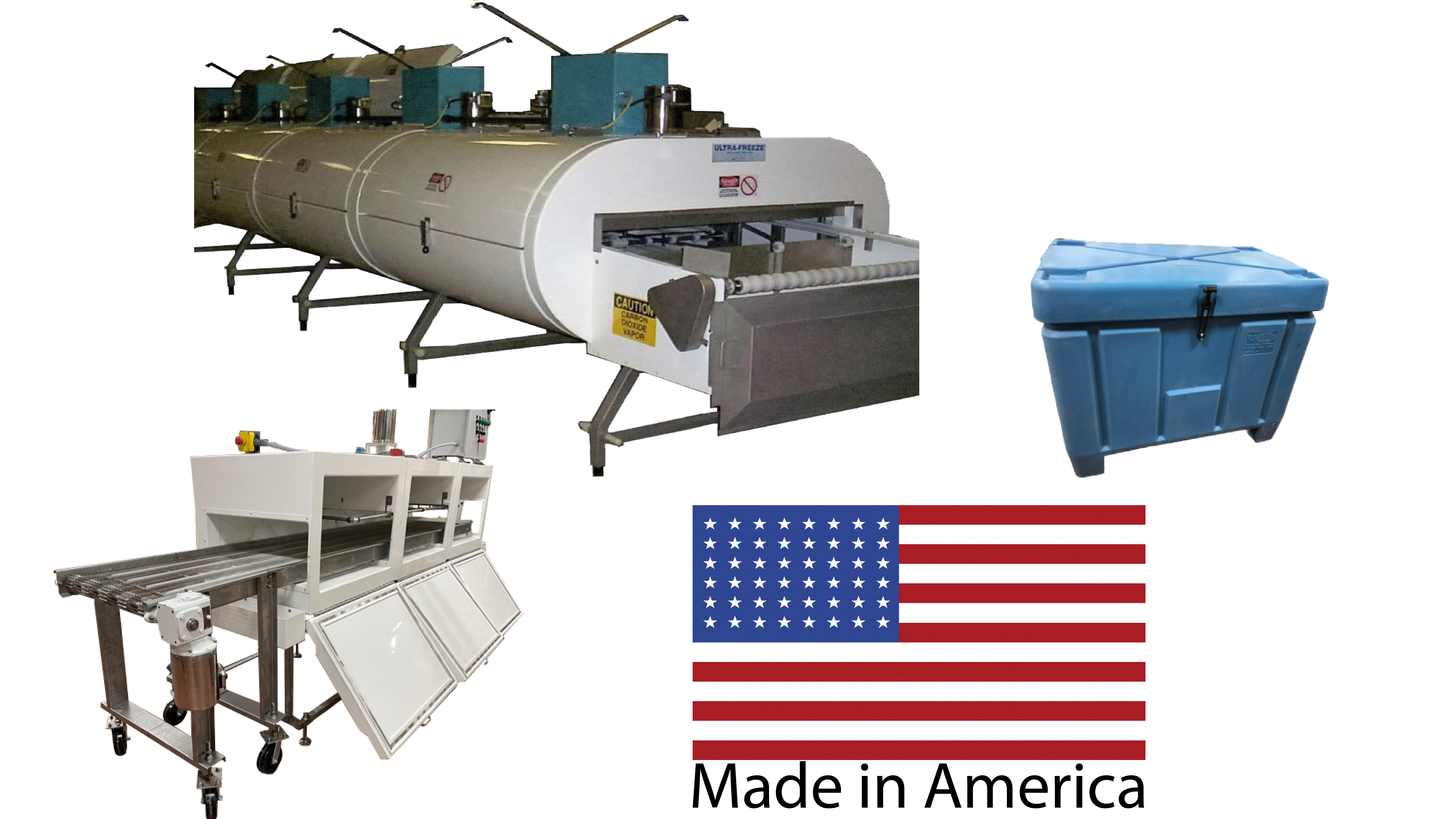

RS Cryo Equipment has experienced and dedicated staff who are willing to go the extra mile for their customers. We specialize in cryogenic equipment; this involves Ultra-Freeze Tunnel Freezers, Cabinet Freezers, 6/8KW Vapor Heaters as well as 18/24 CO2 pressure building Vaporizers, and our new insulated shipping containers.

Cryogenic freezing over mechanical freezing process utilizes the "wind chill" effect to increase the freeze rate for products. The high velocity gas flow created by the circulating fans, continually removes the thin insulating envelope of static gas that normally surrounds the product to be frozen. This allows the cold Nitrogen or CO2 gases to be in very close contact with the surface of food products. The rapid freeze achieved by the high velocity gas flow reduces product shrinkage and moisture loss, as well as maintaining final quality of the product.

Keeping it cold

Insulated Shipping Containers

Insulated Shipping Containers are designed for a multitude of industries including, frozen food, medical, chemical, pharmaceutical industries, dry ice, or any industry where cold temperatures must be maintained for extended periods of time.

Did you know?

Frozen foods last up to 48hrs during a power outage with Dry-Ice!

48hrs not long enough just replinish the Dry-Ice.

Advantages of Cryogenic Freezing Over Mechanical Freezing

Cryogenic freezing offers several advantages over mechanical freezing methods. One of the primary benefits is the ability to preserve the quality of the frozen product for a longer period of time. Cryogenic freezing uses extremely low temperatures to freeze the product -180F vs. -30F for mechanical freezing , which helps to prevent the formation of ice crystals and the degradation of the product's texture and flavor.Additionally, cryogenic freezing can be more efficient and cost-effective than mechanical freezing methods, as it requires less energy to achieve the same level of freezing. Furthermore, cryogenic freezing can be used to freeze a wider range of products, including delicate and sensitive materials that may be damaged by mechanical freezing methods. Overall, cryogenic freezing offers a number of advantages over mechanical freezing methods, making it a valuable tool for a variety of industries.

Advantages of Fiberglass Tunnel Freezers Over Stainless Steel Tunnel Freezers

Fiberglass tunnel freezers offer several advantages over stainless steel tunnel freezers. Firstly, fiberglass freezers are more resistant to corrosion compared to their stainless steel counterparts. This is particularly important in environments with high humidity or chemical exposure, as fiberglass tunnel freezers are less likely to degrade over time.Secondly, fiberglass tunnel freezers are lighter in weight than stainless steel tunnel freezers, making them easier to transport and install. This can be a significant advantage in facilities where mobility and flexibility are important factors.

Lastly, fiberglass tunnel freezers are better insulators than stainless steel tunnel freezers, which can help maintain cold temperatures more efficiently. This can lead to energy savings and a more consistent temperature control, which is crucial for preserving the quality of the products being stored. Overall, fiberglass tunnel freezers offer a more cost-effective and efficient solution for cold storage compared to stainless steel freezers.